The solution to the collapse of foam concrete

From April the French government will reduce fuel taxes slightly to ease the burden on consumers.

Warned of possible energy shortages in France by the end of the year and called on the French to conserve electricity and gas from now on, saying that if nothing was done, The energy situation will be tough this winter. Some experts say that there are two main reasons for France's energy crisis: first, the conflict between Russia and Ukraine affected the gas market and caused supply tension; The second is a safety review of France's newest nuclear power plant, which may lead to a reduction in output this year. In order to alleviate the energy crisis, the whole French society needs to be mobilized, whether it is the industrial sector, the tertiary sector or every French citizen. Now it is urgent. Rising fuel prices may also have an impact on shipments of the foam concrete.

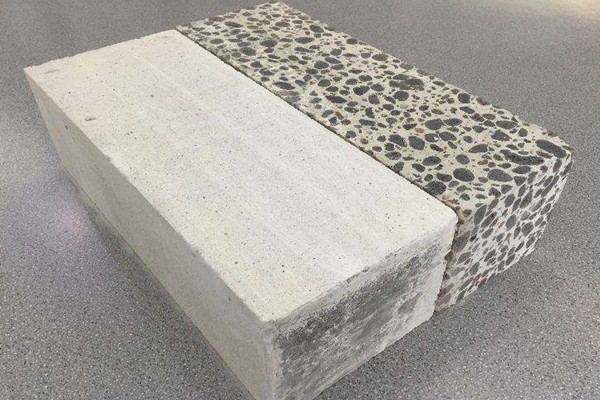

The common problems of foamed concrete are bubbling, cracking, collapse, shrinkage, and other phenomena. To treat these phenomena, the proper medicine can be found, and the cause can be effectively solved.

The main reason for the collapse of foamed cement is that the cement solidification speed is too slow. We can solve this situation from the following aspects

1. Add accelerator to improve the setting time of foamed cement

Accelerators are used in more and more concrete applications. Foamed cement has high requirements for accelerators. It is not just a fast setting but also needs to be adapted to the performance of foamed cement, and accelerators cannot be added. After affecting the foaming situation.

2 Add an early strength agent to improve the early strength of foamed cement and reduce the stress generated during the exothermic process of cement hydration. Only when these two forces are balanced can it be ensured that the foamed cement will not crack and collapse in the later stage.

3. An appropriate amount of sulfoaluminate cement can be added, which many manufacturers choose to use in winter, and the cost performance is still relatively high. However, this amount of addition should also be paid attention to. It should not be added blindly. After many customers add sulfoaluminate cement, the finished product becomes very brittle in the later stage, without toughness, low strength, and severe pulverization. So we still have to adjust according to the current situation.

4 The water-cement ratio is not suitable. Collapse, retraction, bleeding, insufficient strength. To a large extent, it has something to do with the inappropriate water-cement balance. The adjustment of the water-cement ratio is a technical activity that requires trial and error. It has a lot to do with the cement of foamed cement and the fly ash aggregate, and it needs to be practiced repeatedly according to the actual situation. In this, we can add a plasticizer to adjust the water-cement ratio. This effect is very immediate.

The above contents are some solutions summed up by Tongrun according to the reasons for the collapse of foamed cement. If you encounter other problems or reasonable solutions in the actual process, you are also welcome to communicate us.

Recently, the Turkish government announced that the Turkish President has signed a presidential decree to provide incentives for its Black Sea gas field development projects, including tax exemptions and other preferential measures.

With a fixed investment of 145.1 billion Turkish lira ($10 billion), the project will employ 1,018 people and produce 14 billion standard cubic meters of gas per year, the decree reads. The incentives involved include tariff and VAT exemptions, as well as a range of tax cuts.

In June 2021, Turkish drill ships discovered 135 billion cubic meters of natural gas in the Sakaria field in the Black Sea, bringing Turkey's total gas discoveries in the region to 540 billion cubic meters.

Turkey imports almost all of its annual gas consumption of about 50 billion cubic meters.

Except for natural gas, the supply and prices of many other foam concrete will continue to be influenced by international situations.

Inquiry us